Q&A: GS Vortex Flow Amplifier developer Avi Ghosh shares how the new product moves water faster and farther.

Original article written by Mindy Ward, Editor, Missouri Ruralist. Link to original article.

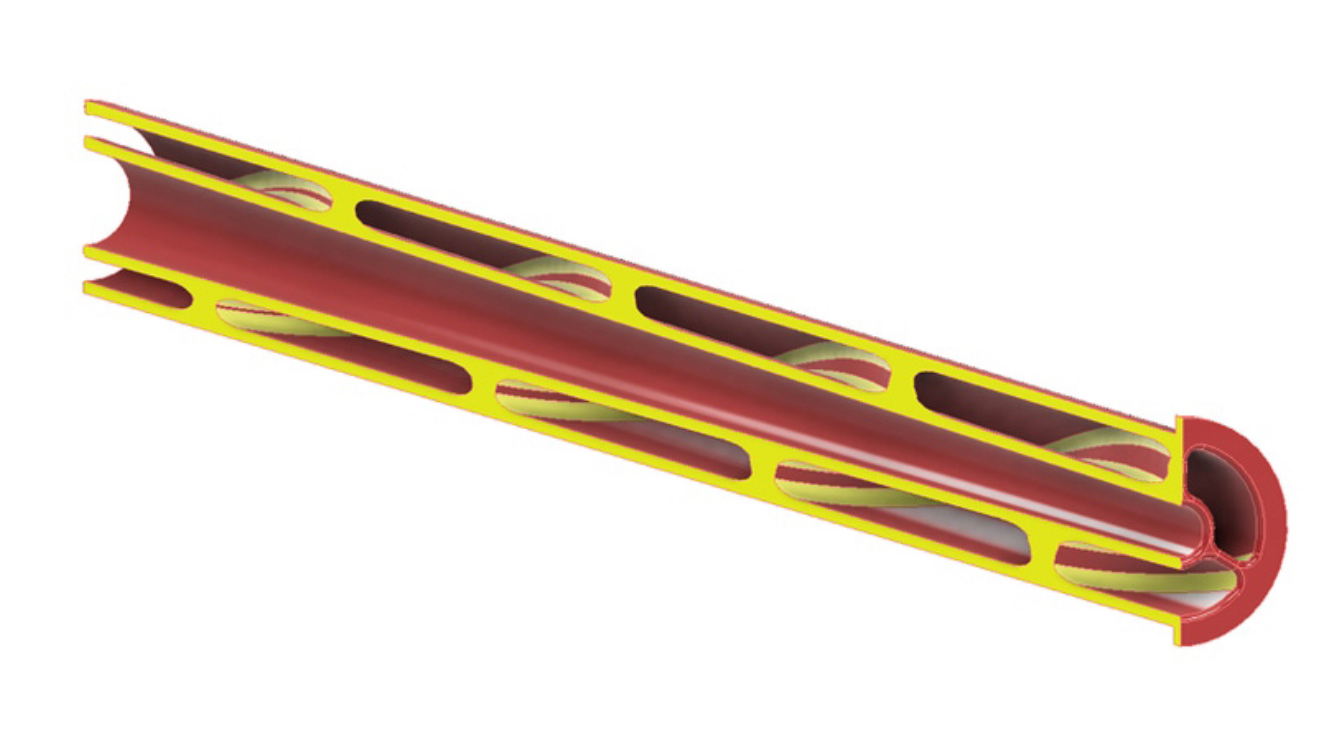

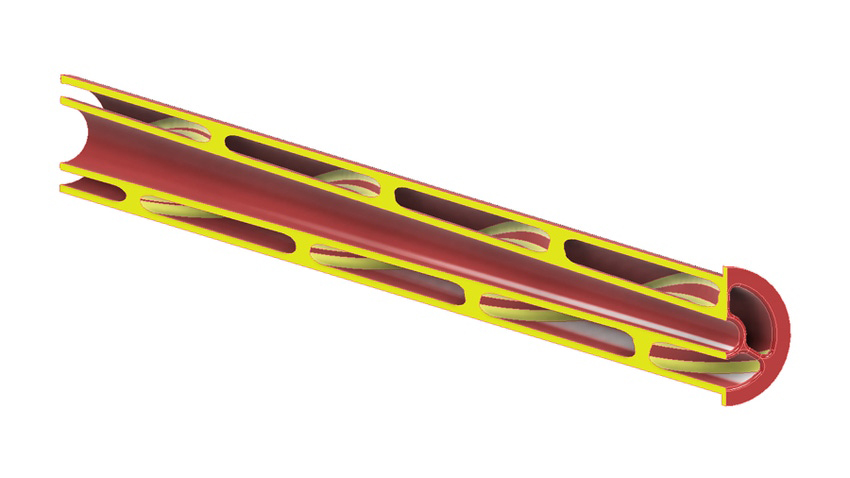

SIMPLE INSERT: The GS Vortex Flow Amplifier fits into an irrigation system to help reduce flow drag and energy use while increasing fluid motion. The idea won the 2023 Agriculture Irrigation Show Pitch Competition. GS VORTEX SYSTEMS

The GS Vortex Flow Amplifier is like a little tornado meeting an old-school bucket brigade.

Making water in irrigation pipes travel faster and farther is the premise of the new GS Vortex Flow Amplifier attachment created by Avi Ghosh, co-founder and CEO of GS Vortex Systems, along with his business partner and director of engineering for the company, Paul Schmidt. The novel concept won the 2023 Agriculture Irrigation Show Pitch Competition in November.

At a time when farmers are struggling with water availability and pumping costs, this product allows farmers to regulate flow from the beginning to the end of the line by simply changing the motion of water inside the pipe.

The product has no moving parts, nor does it require replacement of existing systems. Farmers will use their existing pump and lines, Ghosh says, but the Flow Amplifier will boost performance and reduce cost.

Farm Progress sat down with Ghosh to dive into the details of the new Vortex Flow Amplifier for agricultural irrigation systems implications.

How does the Flow Amplifier work?

Our device creates a pre-rotation and a post-rotation or projection. It is like the movement of a tornado, which is centralizing the flow at an extremely high velocity. So that flow is spinning, rotating all of the water traveling through the pipe. And that has two. The friction on the side of the pipe goes tumbling down almost to zero, so you’re not fighting the friction anymore. And the second is that your pipe is now completely occupied with water and being used at full capacity. Those two things combined give you a lot higher productivity in your delivery of any fluid. Up to 50% higher flow is possible in existing pipes.

The device itself is completely passive, with no moving parts. And it doesn’t need any maintenance, and it does not consume any extra energy.

Does it work from the beginning to the end of the system?

After a time, typical water rotation in a pipe will want to decay; our device won’t let that happen. We will have another device put in place, ready to pick up the rotation from its pre-rotation point. I liken it to a group of people helping each other move a bucket to a fire. People are transporting a bucket, or the rotation is being reenergized each time to continue moving the entire length of your irrigation pipe system. The number of installments depends on the system.

Where does the Flow Amplifier sit in an irrigation system?

The amplifier sits within the pipe at the delivery point. You could go deluxe and amplify the whole system, but that’s not the most cost-effective thing to do. Cost-effective is at the terminal point — is that a direct line, a pivot arm, a wheel line or a drip line? We have amplifier devices for each of those terminal delivery points.

For example, in an overhead irrigation system, you have the riser and the first pivot span. In between those would go a Vortex unit supported with a brace, and that would improve the first flow. Then you repeat the activity all the way down the line. Once it’s installed, you have a permanent improvement in your system.

Can farmers install the product on their own?

They can; it’s super easy. For instance, with a drip-line system, a farmer can go to the point where the water supply needs to be reenergized and snip off a section, take the Vortex Flow Amplifier drip-line unit attachment and place it in. It is that simple. However, for more complex systems, we are on-site initially to show them how to place it in.

What is the energy savings?

Many farmers have a central pump operating several pivots but can’t run them all at once, some because of lack of water or power. It becomes too costly. The Vortex Flow Amplifier allows you to operate a second pivot and take the benefit in terms of yield. Or maybe you need the cost savings, so you are going to turn down the pump and take the energy saving. It gives a farmer a lot of flexibility in terms of savings and productivity.

Just by adding the Vortex Amplifier to an existing closed-loop system there is a 30% energy savings.

Is the Vortex Flow Amplifier available now?

It is currently available. We have been testing with farmers for 30 months, focused on Texas and Oregon. However, we are looking for more farmers across the country to try our product. We want people to do their own trials with their irrigation system on their farm. Every system is unique, and we work with farmers, so they get the most out of our technology.

To learn more about the GS Vortex amplifier, visit gsvortex.com/irrigation or call 713-623-3085.

Vortex Flow Amplifier path to agriculture

Avi Ghosh, co-founder and CEO of GS Vortex Systems, along with his business partner Paul Schmidt, designed the initial system to extend pipe life span for the mining industry, but it is now spilling over into the agriculture irrigation sector.

In mining, companies had to mitigate the volumes of rock and water, known as slurry, which result from the process. “They had to pipe it away,” Ghosh explains. “The debris on the inside was wearing on the pipe.”

Schmidt developed a way for the wear of the pipe to be distributed evenly across and through the system, making the pipe last five to six times longer. And it worked. So, they started looking at other industries where fluid movement is required. Agricultural irrigation was a natural fit.